Created Date: 28 Dec

0 Comments

Getting Started in Woodworking

Beginner Woodworking Tips

Getting started in woodworking can seem like a daunting task. From specialty woodworking tools to identifying and understanding the different types of wood, there is so much to know that even the old-timers are still developing their craft. But learning and experimenting are what woodworking is all about. Get started on the right foot with some essential basics about safety, tools, and lumber as well as the traditional layout and measuring techniques.

01

Safety Rules Every Woodworker Should Know

With sharp hand tools and unforgiving power tools, woodworking can be a dangerous activity. By following some basic safety rules, though, you can considerably reduce the risk of injury. To be effective, safety rules must be implemented every time—no exceptions. Committing to making safety a habit increases your enjoyment and lowers the chance of injury (or worse) while woodworking.

02

Top 10 Hand Tools Every Woodworker Needs

Hand tools are essential for woodworking, and many of the hand tools you'll use most often are ones that you may already own, including:

Hammer

Layout square

Tape measure

Utility knife

Chisels

Level

Screwdrivers

Sliding bevel

Nail sets

Block plane

03

Top 7 Power Tools Every Woodworker Should Have

In the span of woodworking history, power tools are a very recent innovation. However, it is hard to imagine modern woodworking without the use of power tools. That being said, one doesn't need a shop full of expensive woodworking machines to be an effective woodworker. When building a workshop, there are seven power tools to focus on first:

Circular saw

Jigsaw

Power drill

Random orbital sander

Table saw

Compound miter saw

Router

04

The Most Useful Woodworking Machines

Full-size table saws, band saws, and radial-arm saws are examples of woodworking machines that are most often used exclusively in a wood shop because they are far too large and cumbersome to be portable. Even though they're confined to the shop, these workhorses are so useful that it makes sense to complete a woodworking project in the shop and carry the finished piece to the location or job site where it will be used or installed.

05

Selecting Lumber for Your Woodworking Projects

If you have spent any time in a home center or lumberyard recently, you know that there is a lot of substandard material available that may not be usable for a fine woodworking project. Woodworkers learn how to pick through the stack to find suitable pieces of stock to avoid warped, cupped, bowed, twisted, and split boards.

06

The Easy Way to Check for Square

Nearly every woodworking project in one form or another will require you to check some intersection, joint, or board end for squareness, or "square." In some cases, you'll need to confirm that an entire assembly is square. For small projects, you can use a squaring tool, such as a try square, speed square, or framing square. For larger projects, you can check for square by measuring diagonally between opposing corners: The assembly is square when the measurements are equal. You can also use the 3-4-5 method, based on the Pythagorean Theorem: a2 + b2 = c2.

07

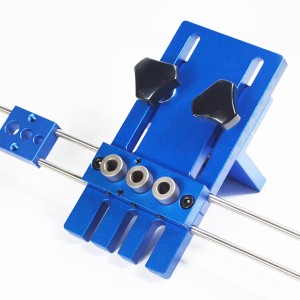

Shop Accessories Every Woodworker Should Have

In addition to woodworking tools, many shop accessories make woodworking tasks safer and easier to complete. These range from simple shop-made jigs to dust collection systems to storage strategies.

08

How to Calculate Board Feet

Hardwood boards and softwood lumber may look similar in shape and dimension, but they are sold using completely different measuring systems. Softwoods are typically sold in standard lumber dimensions (such as a 2x4), whereas hardwoods are most often sold by the board foot. Calculating board feet helps you guarantee that you're getting your money's worth on every piece of hardwood you purchase.

Leave your comment

Note: HTML is not translated!